Enhancing Business Efficiency through PLC Maintenance and Quality Electronic Components Distribution

In today's highly competitive market, maintaining operational efficiency is paramount for businesses across various sectors. One critical element in achieving this efficiency is the effective use of Programmable Logic Controllers (PLCs). Understanding the importance of PLC maintenance and having a reliable partner for electronic components distribution is essential for maximizing productivity and minimizing downtime. This article will delve into these two crucial aspects, highlighting their significance and practical applications in the business realm.

The Role of PLCs in Modern Business Operations

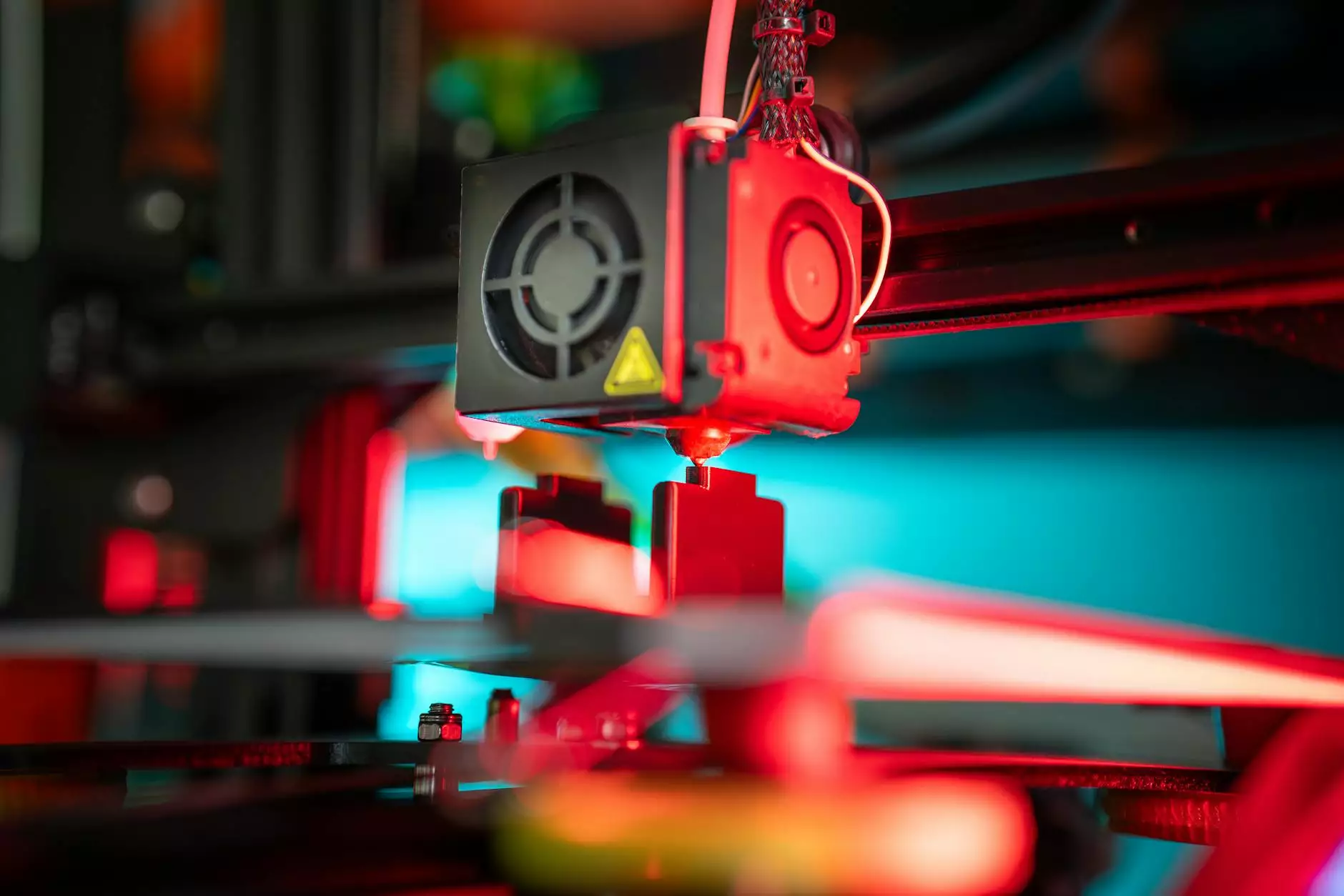

Programmable Logic Controllers (PLCs) are central to the automation of industrial processes. These devices are robust, versatile, and designed to withstand harsh environments, making them an ideal choice for controlling machinery and processes in manufacturing, factory automation, and other industries. The fundamental advantages of implementing PLCs include:

- Improved Accuracy: PLCs minimize human error by automating various tasks with precision.

- Enhanced Productivity: Automation helps in speeding up processes, thereby increasing overall output.

- Scalability: PLC systems can be easily expanded to accommodate growing operational needs.

- Reduced Labor Costs: With automation, businesses can reduce the number of personnel required for manual tasks.

- Real-time Monitoring: PLCs allow for real-time data collection and monitoring, facilitating timely decision-making.

Understanding PLC Maintenance

To ensure that PLCs operate efficiently, regular maintenance is indispensable. PLC maintenance involves a series of systematic procedures aimed at ensuring the reliability and longevity of these systems. The importance of PLC maintenance cannot be overstated, as it directly impacts operational efficiency and cost-effectiveness. Here are some key aspects of PLC maintenance:

1. Preventive Maintenance

This pro-active approach focuses on identifying potential issues before they develop into significant problems. Regular inspections, cleaning, and software updates can significantly reduce the likelihood of unexpected failures.

2. Predictive Maintenance

Utilizing data analytics and monitoring tools, predictive maintenance ensures that businesses can anticipate equipment failures. This approach allows for scheduling maintenance activities at the most convenient times, thereby avoiding disruption in operations.

3. Corrective Maintenance

Even with the best maintenance efforts, failures can occur. Corrective maintenance comes into play when issues do arise, ensuring that repairs are conducted promptly to minimize downtime. Having a reliable partner for PLC repair services, such as QF Automation, is crucial at this stage.

Benefits of Regular PLC Maintenance

Investing in regular PLC maintenance brings numerous benefits to businesses, including:

- Reduced Downtime: Regular maintenance schedules help in preventing unexpected breakdowns that can halt production.

- Cost Savings: By addressing minor issues before they escalate, businesses save on major repair costs associated with equipment failure.

- Extended Equipment Lifespan: Well-maintained PLCs have a longer operational life, maximizing the return on investment.

- Improved Safety: Properly maintained equipment is less likely to fail, significantly enhancing workplace safety.

- Enhanced Performance: Routine maintenance ensures that PLCs operate at optimal performance levels.

Choosing a Trusted PLC Repair Services Partner

When selecting a provider for PLC repair services, businesses should consider the following:

1. Expertise and Experience

Look for a company with a proven track record in PLC maintenance and repair, like QF Automation. Their expertise ensures that qualified technicians handle equipment repairs.

2. Response Time

The ability to quickly respond to repair needs is crucial in minimizing downtime. A reliable provider will have protocols in place to address urgent issues efficiently.

3. Comprehensive Services

Choose a provider that offers a full range of services, from preventive and corrective maintenance to software updates and troubleshooting.

4. Customer Support

Excellent customer support plays a vital role in the maintenance process. Verify that the company provides ongoing support and advice to resolve any operational concerns.

The Importance of Electronic Components Distribution

Alongside effective PLC maintenance, having a trustworthy distributor for electronic components is essential. Distributors like QF Automation play a vital role in the industry by providing high-quality components necessary for system operations. Here’s why electronic components distribution is crucial:

1. Access to Quality Components

High-performance PLCs require quality electronic components. A reputable distributor ensures that customers receive top-of-the-line products that meet industry standards.

2. Broad Product Range

Whether it's sensors, wiring, or control modules, a comprehensive distributor offers various components tailored to different industrial needs. This variety allows companies to source all necessary parts from one location, streamlining procurement.

3. Timeliness and Reliability

Downtime can be costly. A reliable distributor like QF Automation ensures timely delivery of electronic components, so businesses can quickly get back to operations after maintenance or repair work.

4. Technical Support and Guidance

A knowledgeable distributor provides valuable insights regarding product specifications and technical support, which can help businesses make informed purchasing decisions.

Building Long-Term Relationships with Distributors

Establishing strong relationships with distributors is beneficial for businesses in the long run. Here are some tips for fostering positive relationships:

- Open Communication: Maintain open lines of communication regarding needs and expectations.

- Feedback Loop: Provide feedback on products and services to ensure continuous improvement.

- Partnership Approach: Treat your distributor as a partner in success, sharing your long-term goals and challenges.

- Regular Interaction: Engage with your distributor regularly to stay informed about new products and industry trends.

Conclusion

In conclusion, prioritizing PLC maintenance and partnering with a reliable electronic components distributor are critical steps for businesses looking to enhance their operational efficiency. Companies like QF Automation provide the necessary services and components to keep your systems running optimally. Investing in maintenance, alongside building strong distributor relationships, will not only improve productivity but also contribute to long-term success in today’s dynamic business landscape.

By understanding the importance of regular maintenance and seeking quality components, businesses can stand out in a competitive market, ensuring they remain resilient and prepared for the future.